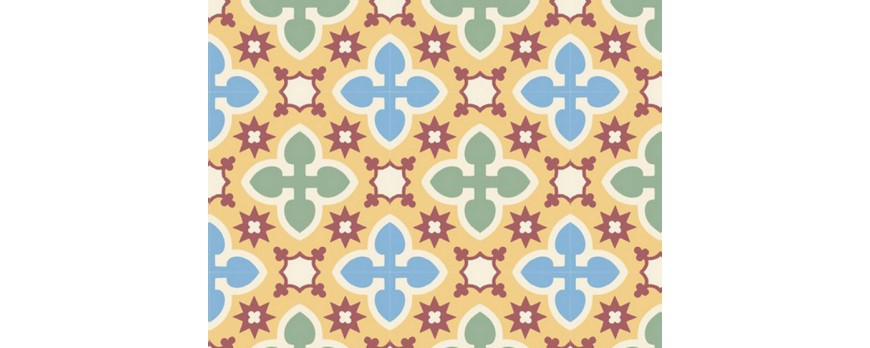

DECORATING WITH HYDRAULIC MOSAIC

The ceramic industry has changed a loto ver the years. Although the principles of tile manufacturing remained the same since the first piece was fabricated, the methods to make it and the finishes have changed a lot. Years ago everything was handmade and each piece had a different treatment to which it is subjected now. Industrialization has caused more resilient and better finished tiles.

Despite this, all process can be summarized in pressing the clay, painting it and finally baking it to finish the manufacturing, although there are other types of floor and wall tiles manufactured in a different way that, therefore, have a different finish. It is, for example, the hydraulic tile. It is manufactured in another way, completely handmade, since the manufacturing process is performed piece by piece.

Each piece of the hydraulic mosaic is manufactured filling a metal mold with a pigmented cement mix that is pressed unit by unit to compact it. Afterwards, is dried for a few hours and later is immersed in water to harden the cement. After a few hours, we let it rest for a few days in a humid chamber. This is the time when the cement reaches its maximum strength and is finished.

For this reason it is called “hydraulic”. Because of the water. Colors and patters of the piece are not obtained painting as in the case of ceramic tiles. The gaps of each form and color are filled with the right mix of cement. This layer is about 4-5 mm. Another layer of the same thickness of cement is placed above it. Finally another more porous layer is positioned to facilitate the placement into the ground.

In the catalog you will find a variety of this type of soil, which gives it a different, elegant and classic touch to the room where it is placed.